How Do Pot Magnets Work? –– Pot Magnet Manufacturers Guide

Pot magnets have versatile properties that have wide applications in various industries and everyday life.

Get to know how pot magnets work, how pot magnets are made, their applications, and how pot magnet manufacturers contribute to a variety of commercial, consumer, industrial needs.

What are Pot Magnets?

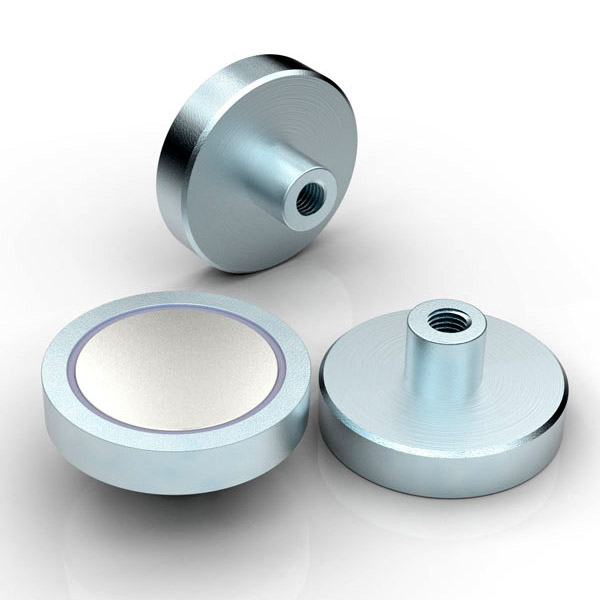

Pot magnets are a type of permanent magnet that is encased in a steel shell. Pot magnets do not lose holding power over time unless exposed to extreme temperatures or external magnetic force.

Pot magnet manufacturers typically supply magnets round pot magnets for holdings, clamping, or mounting.

The most common components of permanent pot magnets are:

Sintered Ferrite

This is a permanent magnet that offers good performance for an affordable price. Ferrite pot magnets have high resistance to demagnetization, corrosion, and temperatures up to 120 degrees Celsius.

Alnico

This permanent magnet is more expensive but offers exceptional performance. Alnico permanent magnets have great holding power and magnetic flux density, corrosion resistance, and temperature stability (maximum 500 degrees Celsius).

Rare Earth SmCo and NdFeB

Rare earth magnets such as samarium cobalt and neodymium offer exceptional functionalities where space and performance are critical.

How do Pot Magnets work?

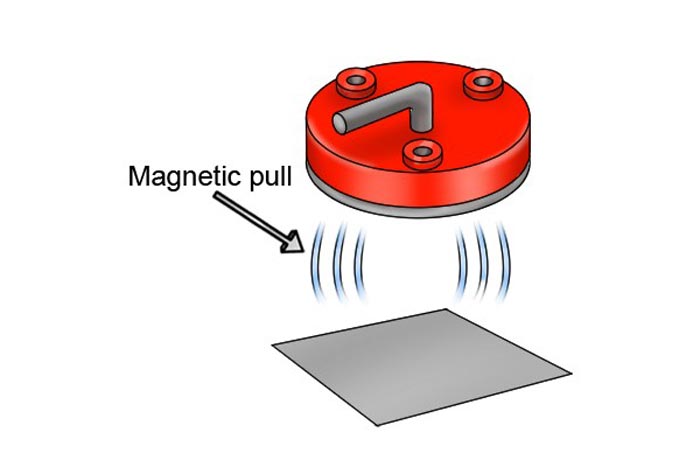

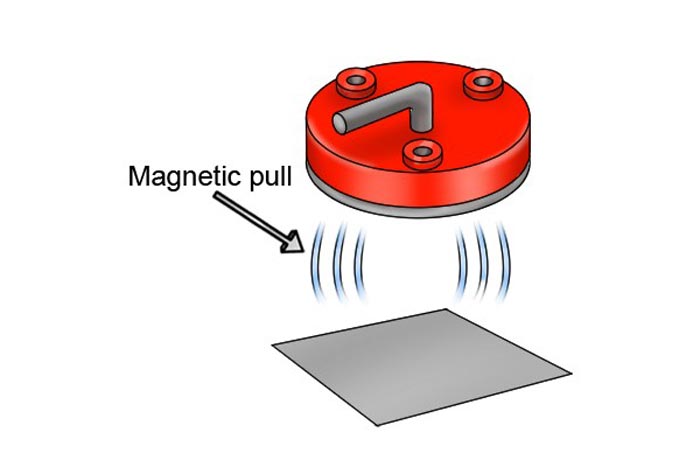

A pot magnet attaches itself to magnetic components through a magnetic field OR to non-magnetic materials with fittings such as threaded holes and pots on top of a steel shell.

This steel shell works to increase magnet holding power, strength, and stability.

What are the advantages of Pot Magnets?

Using ferrite, alnico, and rare earth magnets in pot magnets improves magnet performance significantly:

- Increased magnetic strength: With pot magnets, the magnetic field is concentrated on a single area. This offers greater holding power.

- Durable: With steel or rubber casings, brittle magnets like rare earth magnets are protected.

- Budgetfriendly: Because of the enhanced magnetic force with steel casings, pot magnets can use less magnetic material to achieve the same properties.

- Mounting functionality: With fittings and accessories, pot magnets have a wide selection of applications for daily applications.

How are Pot Magnets Made?

It is possible to get high-quality pot magnets for daily applications from reliable pot magnet manufacturers.

Ensure that your pot magnet suppliers and manufacturers take special care in the production process for long-lasting and reliable magnets.

Step 1: Shaping and casting

Magnet mold is sanded to achieve magnet shape. Generally, ferrite and rare earth are used for flat pot magnets, while alnico and rare earth are used for cylindrical pot magnets.

The magnetic material is then cast and heated in an electromagnetic stove to over 1600 degrees Celsius to melt the metal.

Step 2: Molding

The solution is then poured into the sand mold. The casting mill is opened to cool the material and prevent the sand mold from burning.

The metal is then separated from the sand block.

Step 3: Magnetization

Pot magnets will then be saturated to achieve a magnetic field and establish its direction. Generally, solenoids or a special magnetizing machine is used to impart a magnetic force.

Step 4: Embedding

The magnetized metals are then embedded into steel housing to concentrate magnetic force and increase holding power.

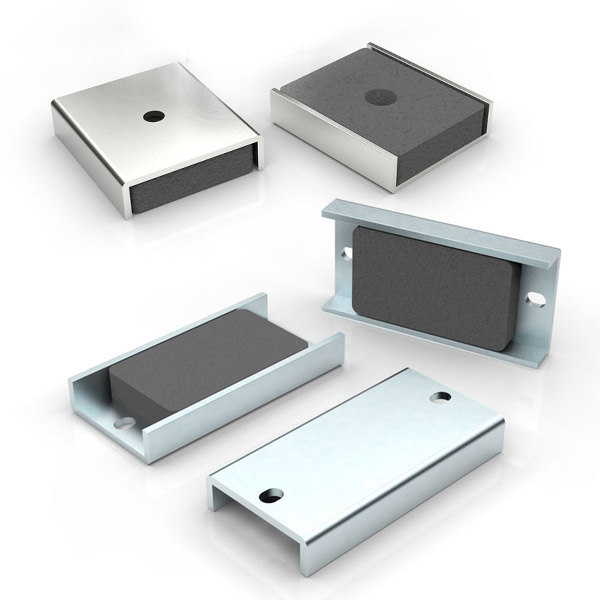

Pot magnets typically have a round base, but pot magnet manufacturers can make a custom cup or pot magnet for you with your desired shape and properties.

Do get in touch with a reliable permanent magnet manufacturer for the costing of custom orders. They will let you know the most efficient and economical method to produce the pot magnets in the quantity and time frame you request.

What are the Applications of Pot Magnets?

Pot magnets are embedded into a wide selection of machines, instruments, and tools across various industries.

Here are the most common uses of pot magnets in daily life:

Industrial Applications

Pot magnets are powerful tools for industrial applications. The most common uses include clamping, lighting, holding, and transport.

Mounting and Hanging

Pot magnets with threaded stems have exceptional strength for various mounting applications in the home, office, and industrial setting. They can be used for mounting signs and banners for marketing and exhibitions, antennas, dashcams, door and gate clamps, and light fixtures.

Searcher and Sweeper Operations

Pot magnets are widely used for searching lost items and salvaging goods, such as deep-sea searches or in hard-to-reach areas (sewers, chutes, pipes).

Where can I find Pot Magnets?

To date, China produces and supplies the largest number of permanent pot magnets. For wholesalers and retailers looking for high-quality pot magnets, we recommend the top magnet manufacturer DailyMag.

Top Pot Magnet Manufacturer in China

Dailymag has been dedicated to answering global magnet demands and needs through continuous research and development endeavors. By providing global solutions to consumer demands, Dailymag is now able to achieve annual revenue amounting to $30 million.

DailyMag Team of Experts

Led by Charles YAO, Dailymag comprises an expert team of researchers, engineers, sales experts, and managers dedicated to producing quality and innovative magnetics in China.

DailyMag works hard to foster trust and long-term relationships with customers on a global scale.

How to choose the best pot magnets manufacturer?

Dedication to Development and World-class Quality

Thanks to Dailymag’s highly professional and passionate team, the company has now acquired the latest technology, machines, and facilities to provide world-class product development and quality.

Dailymang promises to discover new solutions to global needs at competitive prices.

Trusted Customer Support

Some clients might be wary of dealing with an overseas factory and manufacturer.

With Dailymag, wholesalers and retailers can rest easy with reliable and consistent hands-on customer support through email and phone.

Ordering is made easy with a FREE consultation and price quotation. Clients may also request samples and custom pot magnets for their specific needs.

Company Transparency and Certification

When dealing with an overseas manufacturer, make sure to ask for regular documentation of the production process. At Dailymag, you can get consistent and transparent documentation with their factory tour.

You may also view Dailymag's certifications.

Conclusion

Pot magnets manufacturers produce and supply permanent pot magnets for global industrial needs and everyday applications.

Whatever the purpose, you can find quality pot magnets from China magnet manufacturers and suppliers. Contact the leading permanent magnet manufacturer DailyMag for free consultation services, quotations, and magnet samples.