What are Neodymium pot magnets?

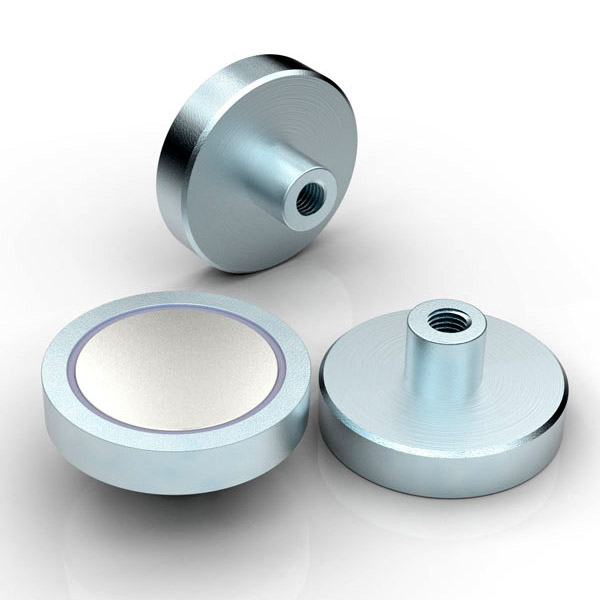

These are magnets, with neodymium - the strongest permanent magnet - embedded within a steel casing or shell. In turn, the steel is coated with a coating of nickel, copper, and nickel again. It is also called a cup magnet, deep magnet, or mounting magnet.

A major feature of the Neodymium pot magnet is the Neodymium magnets which are ferromagnets, composed of neodymium (Nd), iron (Fe), and boron (B). If you combine the chemical symbols of the elements of the alloy, you would get NdFeB which is another name for the magnet. Neodymium is the strongest permanent magnet that has been discovered.

A common feature of neodymium pot magnets (and pot magnets in general) is that only one end is magnetised while the other end is left. As you will soon discover, this characteristic is very important and is largely responsible for some of its properties.

Neodymium pot magnets have a characteristic round base. However, other shapes can be custom made on order.

Due to their insane strength, these magnets are used for holding or mounting heavy objects, separation, lifting, clamping, and many more.

These magnets can be divided into three main parts:

In this case, the magnet is neodymium. Other pot magnets have Samarium cobalt or ferrite.

The spacer separates the magnetic core from the outer casing of steel. This is meant to shield the magnet from any demagnetising influences the steel might have on the magnet. It is made of plastic, epoxy, resin, or brass.

The magnetic core of the neodymium pot magnet is very brittle and cracks easily. Most importantly, the steel encasement contributes greatly to the strength of this magnet as you’ll see later. The steel also protects the magnet from demagnetising forces. Without the steel, the magnet cannot be used outdoors because of corrosion.

Some neodymium magnets are encased in plastic or brass.

The rubber coating is greatly needed for neodymium magnets with outdoor applications. Such magnets are referred to as rubber coated neodymium pot magnets. It protects the magnet from scratching. You can purchase the rubber coating as an accessory.

How do Neodymium pot magnets work?

If you take a look at the magnetic field of for instance a horseshoe magnet, you will discover that the magnetic flux is distributed around the magnet when it is attached to a ferromagnetic material. Hence, the magnetic power is distributed across two ends: the north and south poles.

In the case of pot magnets, it is different.

The steel casing creates a closed magnetic circuit when the magnet is attached to a ferromagnetic material, with the magnetic flux directed towards only one surface vertically to the ferromagnetic surface. This provides for maximum magnetic power on the magnetised end. The magnetic strength is very strong. In addition, the north pole is located at the centre of the magnet while the south pole is on the surface of the steel casing.

Properties of neodymium magnets

- The Curie temperature is between 80-150 degrees celsius. For applications involving temperature above 150 degrees celsius, Samarium cobalt pot magnets or Alnico pot magnets will suffice.

Also, neodymium pot magnets tend to depreciate in magnetic strength with an increase in temperature.

- They have a large clamping force.

- Neodymium pot magnets are axially magnetised.

- One surface is magnetised while the other surface is left like that.

- They have a huge pull force.

-

What determines the magnetic strength of neodymium pot magnets?

Accessories such as rubber casings, reduce the magnetic pull force of neodymium pot magnets.

The best surface for attachment is ferromagnetic (steel or iron), smooth, clean, and devoid of damages. If these conditions are not met, air gaps form between the magnet and the ferromagnetic surface which decreases the magnetic or holding force.

Neodymium has a temperature operating range of 80-150 degrees celsius and a curie temperature of 150 degrees celsius. Hence, temperatures above 150 degrees celsius are not suitable for this magnet.

How is a neodymium pot magnet manufactured?

Neodymium is attached to the spacer and encasing steel, by using a strong glue or adhesive.

What are the properties of neodymium pot magnets?

- The maximum supporting temperature is 150 degrees celsius which corresponds with the curie temperature of neodymium. Hence, it is not suitable for high-temperature applications.

- Only one end is magnetised

- Typically rounded in shape. Other shapes can be manufactured on order.

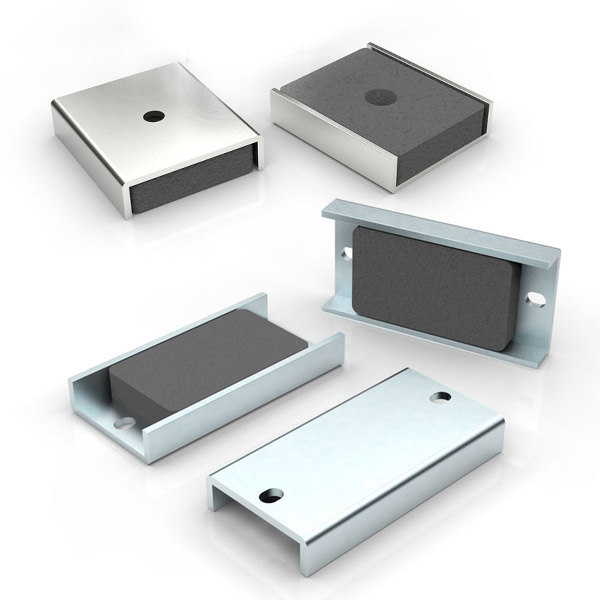

- The encasing is composed of steel, rubber, or brass.

- It has a very high magnetic strength

What are the advantages of using pot magnets?

Unlike other magnets, pot magnets need only a little amount of rare earth magnet. The steel encasing makes the magnetic stronger than even full magnets which have their whole surface magnetised.

To put this in perspective, the job you would require 3 horseshoe magnets to execute can be handled by only one neodymium pot magnet without any hassle.

Pot magnets are able to last longer than other magnets, because of their steel casing. The encasement protects the magnet from the external influence that may deteriorate it.

In addition, the steel is coated with a Nickel-Copper-Nickel coating which prevents it from corrosion.

- Magnetic power is concentrated in one area

Due to the steel covering, the magnetic flux is concentrated on a single area, perpendicular to the ferromagnetic surface it's attached to. Hence, the power is increased.

For instance, a typical pot magnet mounted with a hook can carry weights as much as ten times its size.

- Pot magnets help to hold things in position and connect two surfaces sufficiently.

What are the types of neodymium pot magnets?

- Countersunk neodymium pot magnet

These neodymium pot magnets have a countersunk hole at the magnetic surface which tapers. The hole attaches the magnet to non-ferromagnetic surfaces via screws.

- Internal threaded pot magnet

These magnets have a hole at the centre, threaded spirally on the inside wall of the hole.

- Through hole neodymium pot magnets.

A hole goes through the magnet. The hole is known as a boss. It is used to attach to non ferromagnetic items with a bolt.

There's a magnet centrally located and bordered on each side by a steel pole.

It is far stronger than your normal magnet.

The steel casing protrudes at the top to form a stud.

- Neodymium pot magnet with Hook

- Neodymium pot magnet with eyelet

- Rubber coated neodymium pot magnets

- Hobby and leisure

- Fishing for lost objects

Applications of neodymium pot magnets

Most applications of neodymium pot magnets take advantage of its strength. They include:

They are used to hold things in place. For instance, if you want to hang your mug on a ferromagnetic surface, internal threaded pot magnets can come in handy.

This is especially visible in supermarkets. Internally threaded neodymium pot magnets are used to hold down light to the ceiling.

Pot magnets can be used as a door stopper.

- Jigs

- Retrieval magnets

- Pop displays

- Exhibition display light.

- Gripping components together

Where can I get a neodymium pot magnet?

Dailymag is your premium neodymium magnet manufacturer and supplier. We have customers across the world who have testified to the quality of our magnets. For over 15 years, we have built a strong name as a neodymium pot magnet manufacturer.

Few neodymium magnet manufacturers have the credentials we possess. For over 15 years, we have continually surpassed expectations and received commendations in the process. Our products and factory continue to pass every test put to them by quality assurance bodies.

To ensure quality, we have invested resources to purchase the best machines and hire the best workers. In addition, we only source raw materials from reputable manufacturers such as Total and Formosa.

We continue to produce quality magnets due to the efforts of our research and development team filled with professional engineers and led by professionals who have long years of experience in the field of magnets. As testament to their abilities, we have gotten over 100 patents which are all unique and developed after quality research.

We are aware of the common fear that comes with buying online especially when it comes to machinery. The fear is sometimes unfounded due to the behavior of some manufacturers. Because we listen to you and put you first, we can send you free samples. After trying out the samples, you'll definitely be convinced to make a purchase.

As the saying goes, a company's customer relations gives you an idea of the company itself. We have a professional customer care desk, available 24/7 and ready to guide you along your buying process. They are well versed to give an answer to your inquiries.

So what do you need to do?

Make an inquiry, get a sales quotation from our sales rep, and make an order. We will ship it to your location.