What Are Rare Earth Permanent Magnets?: Guide to Rare Earth Magnets Manufacturer

The demand for China’s production of rare earth permanent magnets skyrocketed in 2020 – the direct result of rising consumer demand for energy power sectors.

Find out about rare earth magnet manufacturers that are increasingly becoming the solution to rapid industrialization and urbanization.

What are Rare Earth Magnets?

Rare earth magnets are vital to modern industrial applications and modern technology because of their high-performing features and precision.

With the development of technology, communications, and industries, the rare permanent magnet industry has rapidly developed.

Global Market

The global rare earth magnet market was valued at $14.4B in 2020. With rapid industrialization, automation, and urbanization, is projected to have a CAGR of 5.9% in the next five years.

China and the Rare Earth Magnet Industry

Asia Pacific is the leading manufacturer of rare earth permanent magnets, with China at the top. China’s production of sintered NdFeB magnets alone rose from 170,000t to 178,500t from 2019 to 2020.

What are the Types of Rare-Earth Magnets?

Rare earth magnets are either Neodymium (NdFeB) or Samarium Cobalt (SmCo). They are the strongest permanent magnets available today. Both magnets differ significantly in physical and magnetic properties and strength, resulting in different applications across commercial and non-comercial industries.

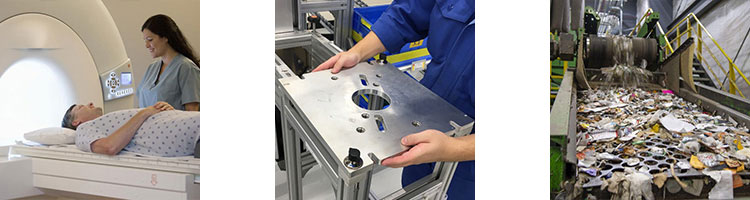

What are the Applications of Rare Earth Magnets?

In recent years, rare earth magnet manufacturers have developed these products rapidly towards improved performance, miniaturization, and versatility of applications.

Rare earth permanent magnets are essential in.

Microwave Communication

Rare earth magnets have the ability to generate constant magnetic force, making it possible to control a magnetic beam for high-frequency oscillation. Microwave amplification, display, and reception.

Rare earth magnets are vital to technology involving radar, satellites, remote control, electronic countermeasure and tracking, cathode ray tube, magnetron electron tubes, and travelling wave tubes.

Electroacoustic Devices

Approximately 15% of rare earth magnets are used to make electroacoustic devices. The current that flows through a magnetic voice coil under the magnetic field vibrates and causes a plate to produce sound – a simple yet reliable technology for producing sensitive and powerful audio devices.

These include speakers, microphones, headsets, telephone receivers, hearing aids, pick-ups, and electroacoustic sensors.

Electrical Engineering

A third of rare earth magnet output is dedicated to permanent magnet motors. These magnet motors vary greatly in type and application, but they are generally used in science and technology and in various sectors of the national economy.

Rare earth magnets require few additional metallic components, findings, and exciters. Rare earth magnet properties have numerous benefits in saving energy and budget due to their compact size, light weight, and high-performance power over any other magnet.

Rare earth magnets are a key design feature for spindle and stepper motors for consumer electronics and the computer peripheral industry. Most hard disk drives, priners, fax machines, cameras, and camcorders use rare earth magnets.

Instruments and Timing Devices

Approximately 10-15% of rare earth magnets is dedicated to magnetoelectric instruments and timers, including the electronic watch.

They are also used in timing motors for industrial robots, space technology, and in the military.

Magnetic machinery:

This field is a new application for rare earth magnets. Magnetic machinery vary greatly in applications, but the principle behind their use of rare earth magnets is the same. For the most part, magnetic machinery takes advantage of same polarities to create a repulsive force and different polarities for an attractive force.

Rare earth magnets are widely used in gears, magnetic bearings, actuators, breaks, clamps, pumps, valves, and locks due to minimal friction and need for lubrication.

Some common applications include:

- Fixing and fastening

- Closure and lifting

- Clamping, positioning, attracting

Transportation Engineering

Maglev trains use mutual repulsion of the same magnetic poles, enough to levitate the vehicle body. This type of train has high-temperature resistance and good temperature stability thanks to rare earth magnet properties. There is no friction, which allows the train to reach high speeds of 500 km/h.

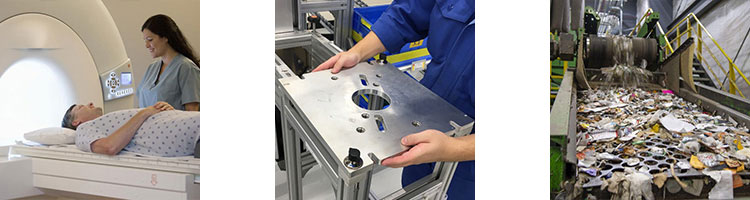

Magnetic Separation

This technique is used to separate magnetic products from non-magnetic products.

Magnetic separation is a vital process in day-to-day global operations including mineral and raw material processing, water treatment, garbage treatment, and food industry

Magnetization Technology

This new field of technology is used to:

- Change the bond state or configuration of atoms and electrons

- Promote chemical reactions

- Promote fuel combustion

Magnetization technology is steadily being adopted to promote growth, remove scale in hard water, and treat human disease.

Therapy and Fitness Equipment

About 10% of the rare earth magnet market is in the medical industry. Common applications are in Magnetic resonance imagine (MRI) and nuclear magnetic resonance (NMR). The high magnetic field is harmless to the human body, compared to radiology and nuclear treatment.

According to some research, magnets have analgesic, anti-inflammatory, and sedative properties. Magnetotherapy is an alternative medicine used to treat insomnia, anxiety, bone, and joint disease, and increase blood supply to the brain, among other medical uses.

Some common magnet equipment used are magnetic sheets, balls, water cups, and shoes, hats, and necklaces.

What are the Available Shapes of Rare Earth Magnets Magnets?

Depending on the application, rare earth magnet manufacturers will create rare earth magnets in different sizes and shapes.

The most common rare earth magnet shapes are:

- Balls: For shaping, polishing, plating, and solidifying,

- Rings: For magnetic applications that need a central hole

- Discs and Cylinders: For drilled holes applications

- Rods and Bars: For noncommercial applications in the home, office, DIY furnishings, and jewelry

- Pots: Used as a magnetic base or for outdoor mounting

Magnet China

Rare earth magnets are widely used in commercial and noncommercial applications. Some of the most notable rare earth manufacturers you will find are from rare earth magnets China.

Top Rare Earth Magnet Supplier and Manufacturer - DailyMag

DailyMag

From our careful research and the reviews of top industries, DailyMag proves to be the leading manufacturer of permanent magnets in China, including rare earth magnets.

After 20 years in the permanent magnet industry, this top-rated manufacturer of ODM and OEM permanent magnets, magnetic tools, and magnetic hardware now has an annual revenue of $30 million.

More on Rare Earth Magnet Manufacturer Daily Mag

Since 2014, Dailymag has put banded together an expert team comprised of engineers, sales experts, managers, and researchers headed by Charles Yao. DailyMag is focused on fully maximizing this team to foster consistent and long-term business relationships that are ultimately centered on creating a total solution to global customer needs.

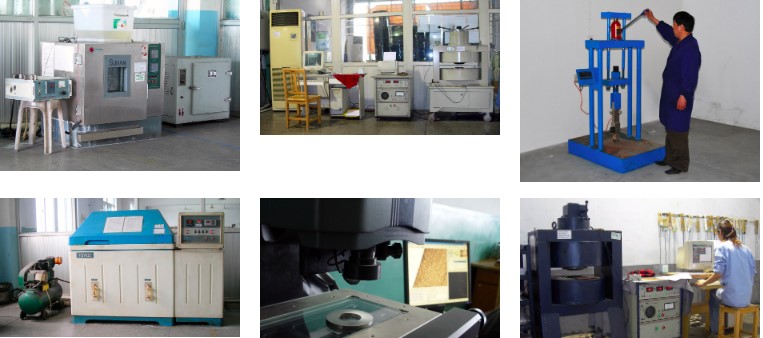

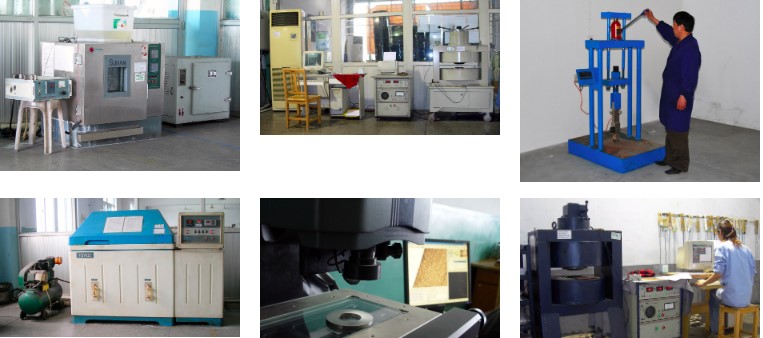

What to look for in rare earth magnet manufacturers?

When looking for reliable rare earth magnet manufacturers, it is necessary to consider quality control coupled with careful anticipation of client needs and responsiveness. Dailymag is a leading company with top-of-the-line machinery and exceptional facilities that ensures quality control and 100% satisfaction guarantee.

For almost two decades, Dailymag has focused on product design and development to release superior products for different global industries at competitive prices. This is all due to continuous research and development to meet international standards. In fact, Dailymag releases 5 to 10 new products annually to meet global customer demands.

When dealing with an overseas manufacturer, another concern is accurate and reliable communications. Dailymag takes charge to address the main customer concerns of customer service and reliability from a Chinese supplier. They offer reliable 24/7 international customer support via phone or email for a free consultation and quotation.

It is inevitable that you run into quality concerns and delays with production and manufacturing with an overseas manufacturer. If you cannot personally visit to ensure quality control, it is necessary to look for a supplier that will send samples and transparent reports and photos.

Dailymag offers a transparent account of their production line with their factory tour and all Dailymag certifications are posted on their website. Dailymag also sends free samples internationally to erase any concerns with a Chinese supplier.

Dailymag is ISO 9001:2008, CE, & RoHS Certified.

Conclusion

China continues to be the manufacturer and supplier of rare earth permanent magnets.

To get the highest quality from rare earth magnet suppliers and manufacturers, it is critical to find the top rare earth magnet solution in China. Because of its careful attention to detail and research and development, DailyMag is one of the leading manufacturers of Rare Earth Magnets China.